The larger the canvas, the more important it is to have it supported by a professionally-made stretcher. For a large work to last over time, it needs a foundation that is light, strong, and skillfully constructed – qualities unlikely to be supplied by anyone other than experts.

Upper Canada Stretchers specializes in making very large stretchers and we have extensive experience with frame dimensions over 30 feet across! Our extra-strong, laminated stretcher bar profiles and sectional, easy-to-assemble splice joints make it possible to create fully keyable stretchers of any size.

15′ x 36′ Heavy Duty Stretchers made for the Royal Ontario Museum, Toronto, Canada

Testing new large stretchers in our shop

15′ x 12′ primed linen on HD Standard Stretcher

Explore Large & Heavy Duty Stretcher Options

10 Special Features of our Large Wooden Stretcher Frames

(1) Laminated heavy-duty stretcher bars for added strength and straightness

As many artists have discovered, it is very difficult to make a straight stretcher bar longer than 8 feet out of solid wood. The longer the bars, the more likely it is that the wood will bow or twist and make the stretcher frame unusable. We have found that the only reliable way to make long stretcher bars strong and straight is to laminate two or more lengths of wood together. Every heavy-duty bar we use in our large frames has been glued and set in clamped jigs to produce very strong, straight and stable stretcher components.

(2) Edge-glued & finger-jointed clear white pine for greater stability

To further improve the structural stability of the stretchers, we use edge-glued, finger jointed clear white pine for our long, laminated stretcher bars. This type of wood is widely used in the window and door manufacturing industry where straight components are critical. Our edge-glued, finger jointed wood is made up of short lengths of clear pine which are finger jointed and glued together to produce very strong, straight and stable bars. The superior strength and straightness comes from the random grain patterns which counteract in each other any tendency to warp.

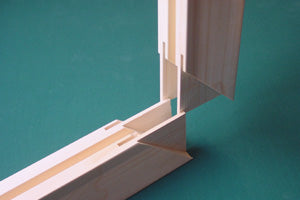

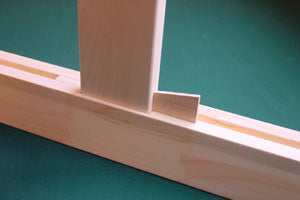

(3) Double/triple tongue & groove friction joints for stronger corners

All of our heavy-duty stretchers have extra strong double (Heavy-Duty) or triple (Extra Heavy-Duty) tongue & groove friction-fit joints at the corners of the frame. This means that each corner of our large stretcher frames has four or even six fully keyable friction-fit connections.

(4) Heavy-duty cross-braces for maximum support and clearance

Our heavy-duty frames use 3/4” or even 1-1/8" x 3” pine braces, which provide excellent support for the stretchers while still allowing the required amount of clearance from the canvas.

(5) Fully Keyed Bars and Braces

Since large canvases are more prone to sagging over time, it is especially important to have the canvas supported by a stretcher frame which can be “keyed-out” to maintain the required tension. All of our large stretcher frames are made with keyable corner and brace joints.

(6) splice-jointed sectional designs for ease of shipping and assembly

The only practical way to ship a large stretcher frame over 8 feet is to make the long bars and braces in shorter sections that are bolted together at assembly. We use flush mounted hex-head connector bolts for fastening all splice joints (where bar or brace lengths overlap).

(7) Folding Stretchers for Easy Transportation of artwork

With our splice-jointed sectional frame designs, it can be possible to fold a large canvas in two or more panels without having to remove the canvas. This saves a considerable amount of time and effort in situations where large paintings must be moved to new locations or even just around corners within buildings.

(8) Space for a protective backing

All of our heavy-duty stretcher frames have inward slope on the back side which allows for installation of a protective backing, if desired. Backing can be critical to the longevity of a work of art as it makes a barrier or buffer to reduce the effects of cycling climatic changes and atmospheric pollutants, and to reduce the risk of damage caused by mishandling.

(9) Easy Assembly – Instructions and hardware provided

With each stretcher frame shipped, we include detailed instructions along with any hardware (bolts) required for assembly and "keying out" (adjusting) of the frame. Every frame is assembled in our shop before shipping and each joint and stretcher bar/brace component is labeled to facilitate easy reassembly. An extra large stretcher frame (10’ x 20’) typically would take about one hour to assemble.

(10) Use Gravity Bars for Proper Installation

Because of the increased weight and dimensions of large canvases, it is important to provide proper support to avoid damaging the artwork or the wall. Hanging the painting using gravity bars is an effective and simple way to accomplish this. The top halves of the gravity bars are typically fastened to the vertical or horizontal braces on the stretcher frame at a spacing of about 3-4 feet across the width of the frame. The bottom half of each gravity bar is fastened to the wall; the force of gravity holds the painting securely against the wall.

No matter how large, our frames are designed to reduce your work on assembly to a minimum of effort and hassle. Consult with us on how we can provide custom-designed stretcher frame assemblies for your very large canvas sizes or works requiring exceptional strength & dimensional stability.

For very large sizes or when other requirements dictate, we also offer keyable aluminum stretcher frames.

Get a Quote for Your Next Large Canvas Stretcher